Driving behind a semi-truck at night without clear lighting causes confusion and danger. Poor visibility can lead to accidents. Knowing essential truck lights and choosing right ones improves safety and compliance.

Semi-truck lights are called commercial vehicle marker and safety lighting, including headlights, tail lights, brake lights, turn signals, clearance lights, side marker lights, identification lights, fog lights, license plate lights, and auxiliary work lights. These lights ensure visibility, communicate driver intent, and comply with DOT and FMVSS 108 regulations for road safety.

To understand every light and choose compliant lighting, continue reading the full guide below.

Why do semi-trucks need so many different lights?

Semi-trucks are significantly larger than passenger vehicles, typically 70–80 feet with trailer combined. Their long structure creates multiple blind-zones and requires enhanced visibility so others can identify the vehicle’s size and movement. Regulations from the U.S. Department of Transportation (DOT) and the Federal Motor Vehicle Safety Standard 108 (FMVSS 108) mandate specific lights in exact positions, sizes, and colors.

Truck lights serve three primary functions:

-

Illumination – ensuring drivers can see the road and hazards.

-

Identification – helping other motorists recognize the width, height, and orientation of the truck.

-

Communication – signaling braking, turning, reversing, and lane intentions.

Without proper lighting, the risk of rear-end and side-collision accidents increases sharply, especially during night driving, rain, snow, fog, and poorly lit roads. Fleet operators rely on compliant lights to reduce liability, avoid fines, and maintain operational safety.

The main types of semi-truck lights and their names

Below are the essential lighting components used on tractors and trailers:

1️⃣ Headlights

Mounted on the front of the tractor, headlights illuminate the road. They include:

-

Low Beam: used for standard night driving

-

High Beam: extended visibility on dark highways

-

Daytime Running Lights (DRL): automatic lights for daytime visibility

Most modern trucks upgrade to LED headlights for better durability and lower energy consumption.

2️⃣ Trailer and Tractor Tail Lights

Positioned at the rear, tail lights ensure the truck is visible from behind. They light up when headlights are on and also include rear position lamps.

3️⃣ Brake Lights

These activate when the driver applies the brake pedal. They communicate deceleration and prevent rear-end collisions.

4️⃣ Turn Signal Lights

Amber indicator lights at the front, sides, and rear notify lane changes and turning direction. Trucks often include additional sequential or extended side turn signals for improved visibility on long trailers.

5️⃣ Clearance Lights

These amber (front) and red (rear) lights define the truck’s extreme height and width. Any commercial vehicle over 80 inches wide must have them by law.

6️⃣ Side Marker Lights

Located along trailer sides, these help other drivers judge vehicle length and movement. They’re usually amber towards the front and red at the back.

7️⃣ Identification Lights

Three grouped red lights at the rear top and three grouped amber lights at the front top. Their purpose:

-

Identify the vehicle as a large commercial truck

-

Warn others of wider-than-standard dimensions

8️⃣ Fog Lights

Low-mounted auxiliary lamps that cut through fog, snow, or heavy rain using a wide and short beam.

9️⃣ Reverse (Backup) Lights

White lights that illuminate when the truck is in reverse gear, alerting pedestrians and other vehicles.

🔟 License Plate Lights

Small white lights required to illuminate the vehicle’s rear license plate.

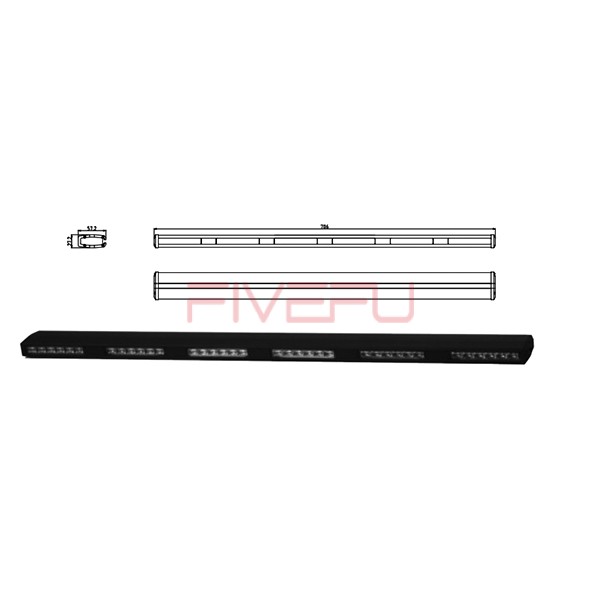

11️⃣ Work Lights (Optional)

Mounted behind the cab or at the rear of trailer for loading, docking, and nighttime operations. These may not be used as road-facing lights while driving.

Why LEDs are now the top choice for semi-truck lighting

Fleet owners are rapidly shifting from halogen and incandescent lamps to LED lighting due to several advantages:

| Feature | LED | Halogen/Incandescent |

|---|---|---|

| Lifespan | 30,000–50,000 hours | 500–2,000 hours |

| Power Efficiency | Very high | Low |

| Vibration Resistance | Excellent | Poor |

| Brightness | Strong and directional | Diffused, weaker |

| Maintenance Costs | Low | Higher long-term |

LED lights also improve:

-

Visibility range

-

Color accuracy (more natural white light)

-

Reaction recognition from other drivers

LED compliance labeling (DOT, SAE, E-Mark for Europe) is critical to avoid penalties.

Regulations you must follow: FMVSS 108 and DOT rules

Every light on a semi-truck is regulated, including:

-

Lighting color requirements

-

Number and placement

-

Reflector integration

-

Visibility angles

-

Brightness levels

Color compliance summary:

-

White – headlights, backup lights, license plate light

-

Amber – front clearance lights, side markers, front turn signals

-

Red – rear clearance lights, brake lights, tail lights

Trucks found using illegal lighting colors or unapproved modifications may receive fines and fail safety inspections.

How to maintain truck lights for maximum safety

To keep commercial vehicles compliant:

✅ Perform daily pre-trip inspections

✅ Check lens cracks, water intrusion, loose connections

✅ Clean dirt and snow blocking light projection

✅ Replace dimming or flickering bulbs immediately

✅ Use waterproof, vibration-rated LED housings

✅ Ensure wiring follows standard polarity and grounding

Lighting issues are one of the most common causes of DOT citations — regular checks prevent downtime and accidents.

Semi-truck lights include headlights, tail lights, brake lights, turn signals, and marker lighting such as clearance, side marker, and ID lights—all enforced by DOT rules for safe road operations.